New motors save money

Information

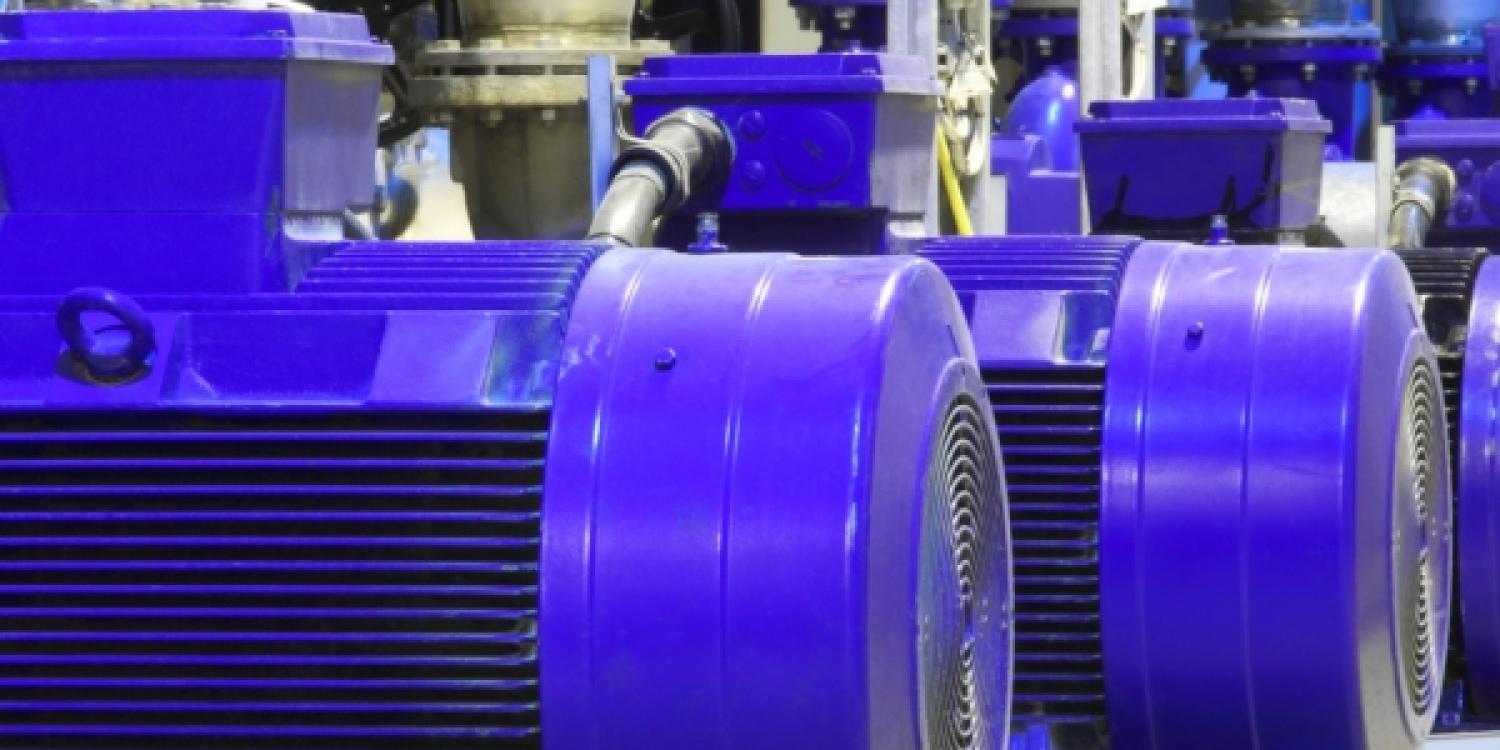

Motoring along more efficiently than ever

- One-off investment of € 2 000 in more efficient and controllable motors yields results

- Annual cost savings on energy come to around € 800, equivalent to a 1.6 tonne CO2-reduction

Chemotechnische Abpack-Service GmbH (CAS) is a small company from Germany, which offers packaging and filling services for various liquid products. The company fills materials like silicone, polyurethane, polysulfide, epoxy resin, colour paste and lubricants in tubes, cartridges, tins and foil bags. Customers come mainly from the automotive industry, as well as the construction, aeronautics, glass, wood and metal sectors.

Several motors are used as part of the company's packaging/bottling operations. Many of the motors were shown to be inefficient or not well optimised. In total, nine of the 15 motors run constantly during the process, independent of demand.

With a one-off investment of € 2 000, CAS was able to replace the old motors with new, more efficient units that have more control options and settings.

Key results

As a result of this one-off changeover, the company uses 2 500 kWh less energy per year, which leads to cost savings of € 800. This is equivalent to a CO2-reduction of 1.6 tonnes in a given year.

Effizienznetz Rheinland-Pfalz, Kosten Sparen durch ressourceneffiziente Abfallentsorgung, https://effnet.rlp.de/fileadmin/effnet/Praesentationsblaetter/Chemische…