Meat and food company saves through continuous improvement

Information

Thinking holistic...

- Production development programme is key to continuous improvement in meat/food company

- It factors in production, materials and sustainability in a holistic approach

Finnish meat and food company Atria's main principle is continuous improvement. Atria's aim is to further improve its use of raw materials and resources like water and energy through a production development programme. The programme has been running for a few years.

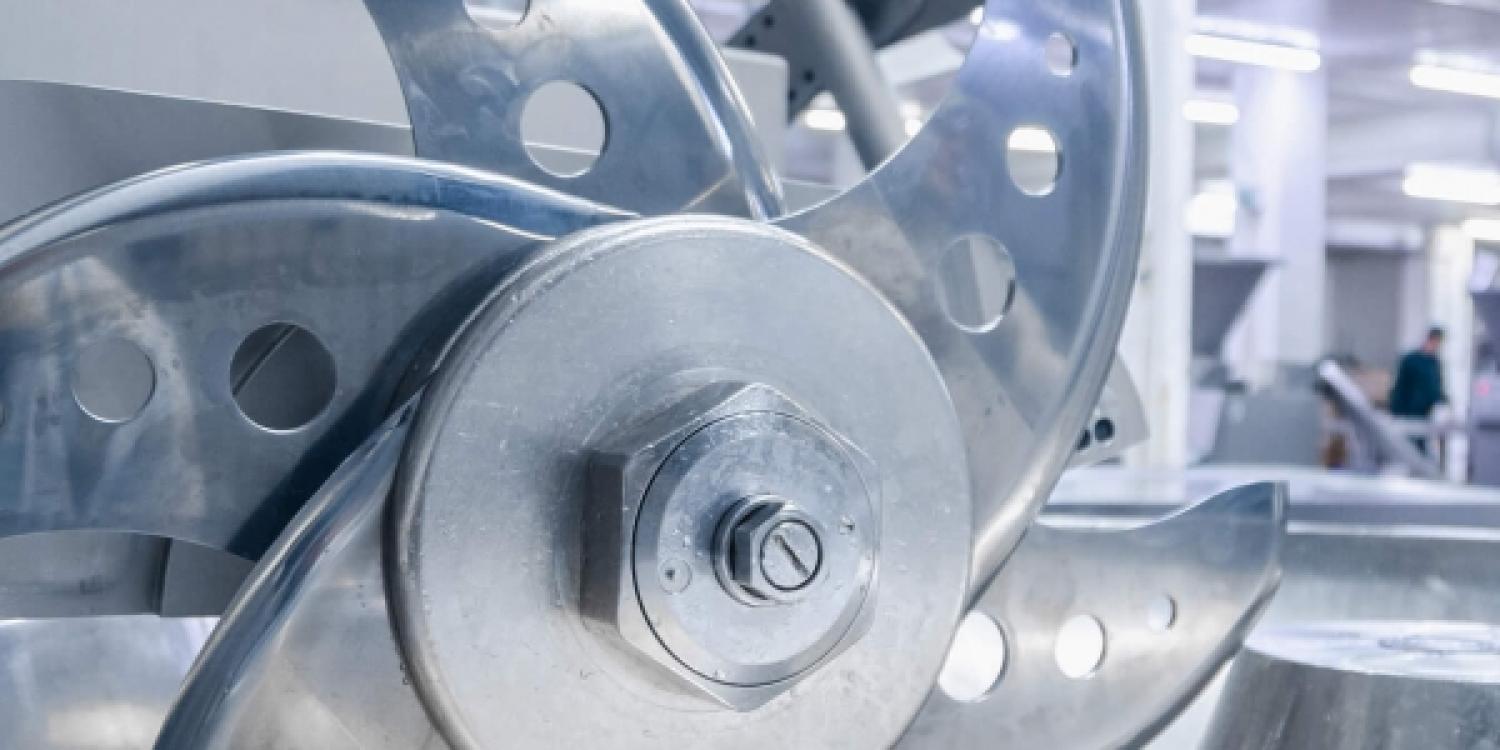

For example, Atria has developed production methods and cutting processes for its chicken business so that the most valuable part of the chicken, the fillet, is better used. This also reduces the overall raw material needs.

The material efficiency measures have brought annual savings of about € 1 million. Optimising water consumption alone has resulted in annual savings of € 100 000. The compan also saves around 1 500 MWh per year on primary energy used in heating; around the same consumption as 100 single-family houses.

In addition to the production development programme, Atria has also invested in energy efficiency through heat recovery. For example, condensation heat from the cold compressors is used to heat the washing water and premises. It replaces primary heat demand by about 70 000 MWh per year, or around 5 000 average single-family households.

Key benefits

- The material efficiency measures under the production development programme have brought annual savings of about € 1 million

- Optimising water consumption alone has resulted in savings of € 100 000 annually

- Primary energy heating savings of 1 500 MWh annually

- Reduced total raw material needed

- New operational models

Atria Finland’s production development programme (in Finnish)(2019), https://www.atria.fi/konserni/tyonantajana/me-atrialaiset/mita-kaikkea-me-teemme/tuotanto/boost--tuotannon-kehittamisohjelma/

Example of material efficiency measures of Finnish food company, Motiva's website (2019), https://www.motiva.fi/ratkaisut/materiaalitehokkuus/materiaalitehokkuuden_sitoumukset/elintarvikealan_sitoumus/esimerkkeja_yritysten_toimenpiteista/atria_-_hyvaa_ruokaa_resurssiviisaasti

Atria’s Responsibility Report 2018, https://www.atria.fi/en/group/news/publications/corporate-responsibility-report-2018/