VIDA Awarded Project - ISV022 - Olive Mill Wastewater Treatment with the advanced oxidation from VoDCa, a device for Vortex and Cavitation

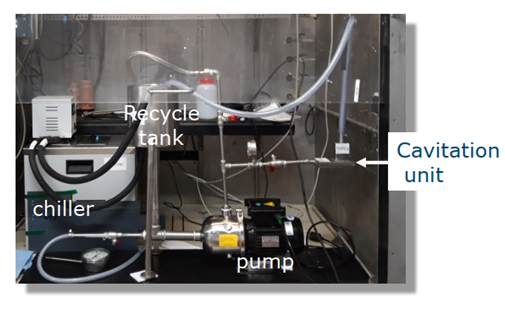

Experimental setup

Duration:

19 September 2019 / 19 March 2020

Summary:

The food industry is by far the largest potable water consuming industrial activity per ton of food product. In the operational water footprint assessment one litre of olive oil can generate 1-1.2 litres of wastewater.

Olive Oil Wastewater (OOWW) has a high environmental impact and is characterized by its high COD, BOD, suspended solids, high salts content and a very high toxicity phenolic compounds due to which its biological treatment is not feasible. Advanced oxidation technologies that harness the potential of OH radicals are quiet expensive on the CAPEX and OPEX that employ O3/UV/Tio2. Biological oxidation is not only ineffective due to the toxicity attributed phenolic compounds to the bacteria but also expensive due to a typical scale of operation that OO Mill producers are practicing.

Regulations to treat OOWW have been enforced in Italy by an environmental law to treat or eliminate their wastes and it is expected that sooner or later other olive oil producing countries such as Greece, Spain, and Portugal may have to follow a European directive to treat OOWW. OO mills are thus looking for alternative technologies that they can afford at a small scale and also have a small footprint, chemical free and is commercially viable.

Water Knight offers VoDCa , a patented technology of Vortex Cavitation, to treat industrial wastewater treatment applications with complex effluents. VoDCa tests were carried out on the waste water samples received from the Spanish olive oil mill producer with the key objective to reduce the bulk load of high pollution in OOWW (characterised by Chemical Oxygen Demand, COD). VoDCa treatment on OOWW with a very small amount (100-200 ppm) of Hydrogen Peroxide addition resulted in a COD reduction of circa 50-70% in 30-60 minutes of treatment time. The encouraging results from the VIDA feasibility project provide a clear evidence for the potential of VoDCa Technology in the olive oil processing market. Considering the complexity of the OOWW and the limiting conditions such as capex, footprint, and practicalities of required operating protocols in its treatment, the revealed results from the robust technology of VoDCa demonstrated a promising approach to treat OOWW.

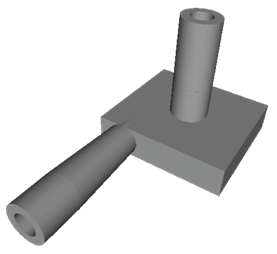

VoDCa ( Vortex Device for Cavitation)

Partners:

Water Knightwww.waterknight.com

Learn more: www.vidaproject.eu I info [at] vidaproject.eu ( ) I Follow us: @h2020vida

This project has received funding from the European Union’s Horizon 2020 Research and Innovation programme, under Grant Agreement nº 777795.

Disclaimer: The content of this document represents the view of the author only and is his/her sole responsibility: it cannot be considered to reflect the views of the European Commission and/or the Executive Agency for Small and Medium-size Enterprises (EASME). The European Commission and the Agency do not accept responsibility for the use that may be made of the information it contains.