PETinject researches industrial technologies to manufacture PET packaging from recycled material

- The project involves 6 companies from different parts of the packaging industry value chain, under the coordination of the Packaging Cluster, BertIA, Industrias Plásticas Triana, KUKA, Molmasa, Tepsis and VM Systems

- The objective of this collaborative initiative is the development of a system that allows the manufacture of packaging for food and cosmetic use, with post-consumer recycled PET

- The integration of different industrial processes in a single automated and digitised system will allow greater efficiency and productivity in IP Triana's plants, a scalable solution for other manufacturers

Packaging Cluster, an entity that represents more than 130 key players in the packaging sector, coordinates the PETinject project, a business initiative formed by BertIA, Industrias Plásticas Triana, KUKA, Molmasa, Tepsis and VM Systems. The 6 companies and the cluster are working together to find a system for the production of recyclable PET packaging that integrates the moulding process, digitalisation and automation to make it much more efficient and sustainable.

For some months now, the consortium has been investigating how the manufacturer of plastic injection moulded containers, Industrias Plásticas Triana, could incorporate a new industrial process at its production plant in Barberà del Vallés, with which to manufacture PET packaging, suitable for foodstuffs and with a high recycling capacity.

To this end, IP Triana and Molmasa, specialists in the manufacture of moulds and industrial solutions, will focus on the research, design and development of the first injection mould, as well as the construction and testing of this new technology, which will allow it to be integrated into the current production system.

On the other hand, VM Systems, developers of automation systems, will create a robotised container handling solution for the demoulding of containers, as well as the packing stage, with a quality control station.

Tepsis will lead the development of the system to capture data from the different elements involved in the process and define the architecture to store them in the IP Triana database.

From here, BertIA will develop a descriptive data analysis model that will allow IP Triana to determine the optimal functioning of the equipment and elements involved in this advanced process, analysing the productivity, the variables of the different systems and the quality of the final product, and to be able to provide possible limitations or failures.

Last but not least, KUKA Iberia and VM Systems will be in charge of digitalising the robotised PET container handling process, connecting the virtual environment with the physical one.

A sustainable and scalable solution for other packaging manufacturers

In this way, the PETInject project aims to develop an alternative to current PET packaging manufacturing systems, researching a new mould, with a complete process of automatic systems and with a full level of digitalisation and data processing.

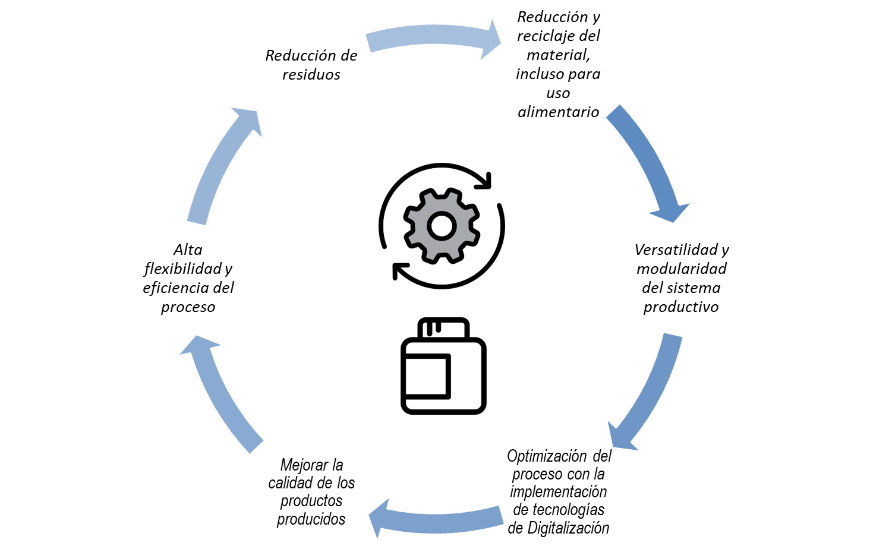

The result of these months of work will boost the use of sustainable and recyclable materials, such as PET, and will promote the transformation of the sector, as industrial packaging manufacturing companies will be able to replicate the model and follow the trends towards a more circular economy:

What is PET?

PET (Polyethylene Terephthalate) is a polymer discovered in the early 1940s with the aim of manufacturing fibres, which today allows the creation of thermoplastics that are resistant, light, transparent, with barrier properties and with a great capacity for recycling. The example that first comes to mind is the water bottle, but there are products such as tuppers, shampoos, carafes, cosmetic bottles, dishwashers, vinyl or even clothing, which are made from PET.

The fact that PET is 100% recyclable and can be used in the food sector makes it one of the most promising materials on the market, as the European Circular Economy Strategy for plastics states that by 2030 all plastic packaging distributed in the European Union must be 100% recyclable.

PETinject project has been funded by the Ministry of Industry, Trade and Tourism through the support programme for Innovative Business Groups (AEI), within the framework of the Recovery, Transformation and Resilience Plan, with the aim of improving the competitiveness of small and medium-sized enterprises.